-

Precision and

ReliabilityDiscover how you can get complex shapes manufactured at competitive prices

-

Precision and

ReliabilityDiscover how you can get complex shapes manufactured at competitive prices

-

Precision and

ReliabilityDiscover how you can get complex shapes manufactured at competitive prices

Since 1982,

production of

sintered components

Since 1982, Investarm sinterizzati has produced sintered components from iron, alloy steel, brass, bronze and copper.

The sintering process consists of heat treatment in a controlled atmosphere, applied to a component formed by double pressing metallic powder to create a shape with mechanical properties requested by the customer.

Our Machines

Mechanical and hydraulic presses

Flexible Supply

Small and big lots

Production lots

Raw Materials

Standard and special productions

Standard and custom powder mixes

Sintered

Products

Sintering technology is has many applications in various industrial fields. Flexibility and precision of this production process allow to create a wide range of products.

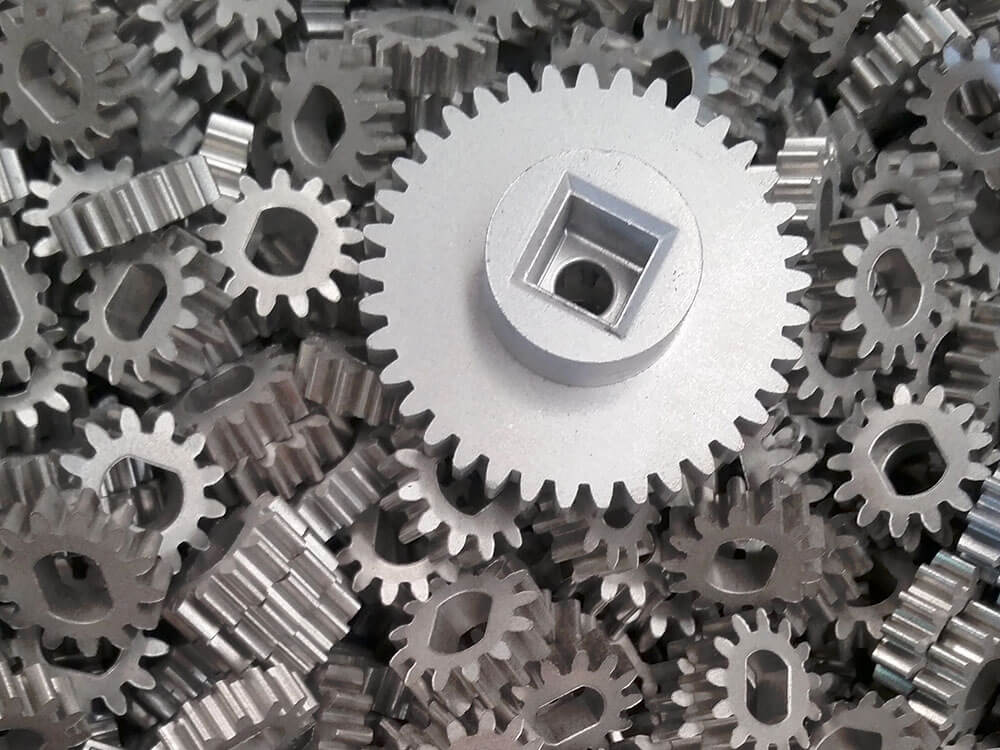

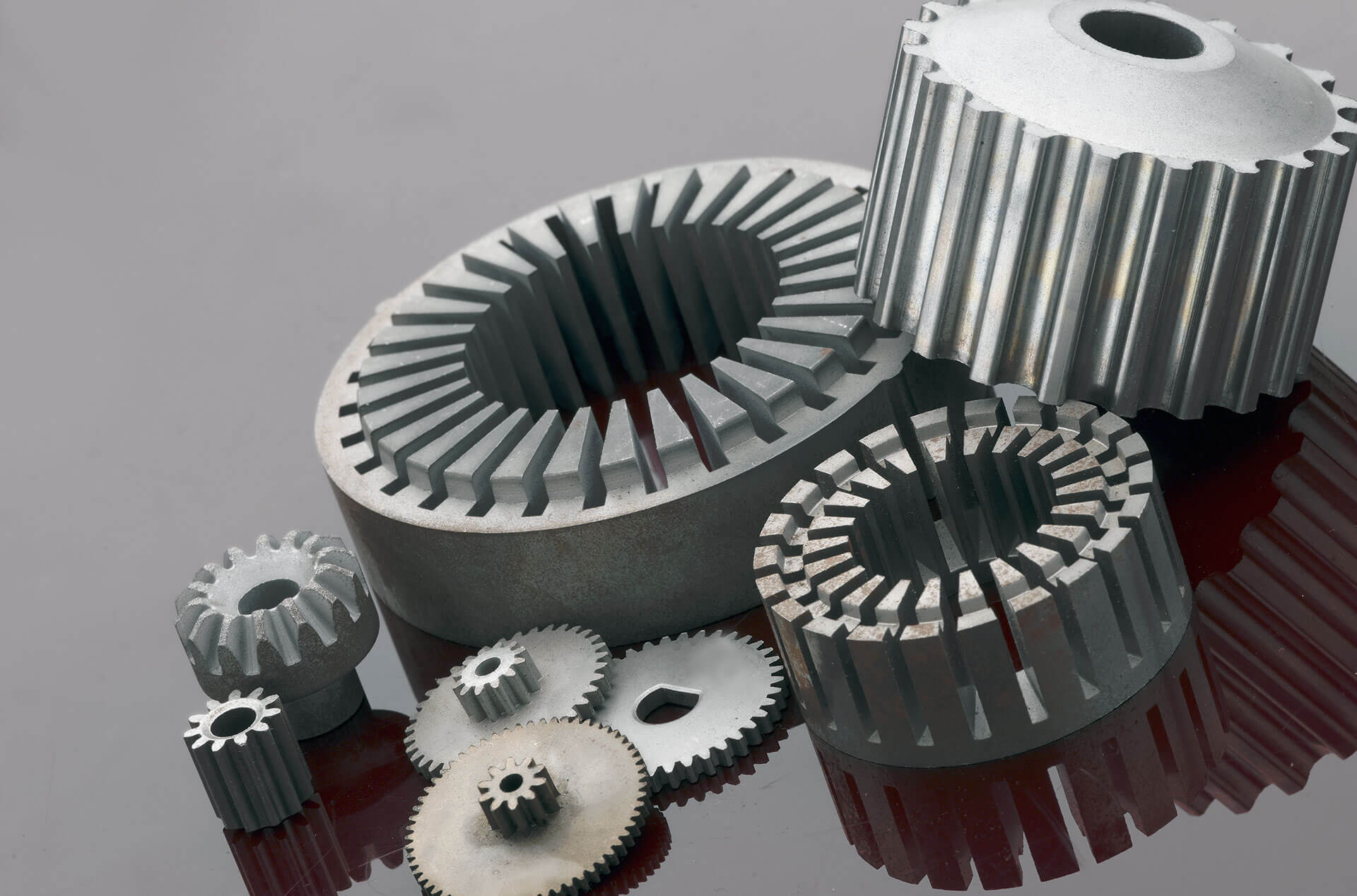

Gears

Investarm's experience in sintered gears covers many different applications, such as: household electrical appliances, textile machines, bicycles, etc.

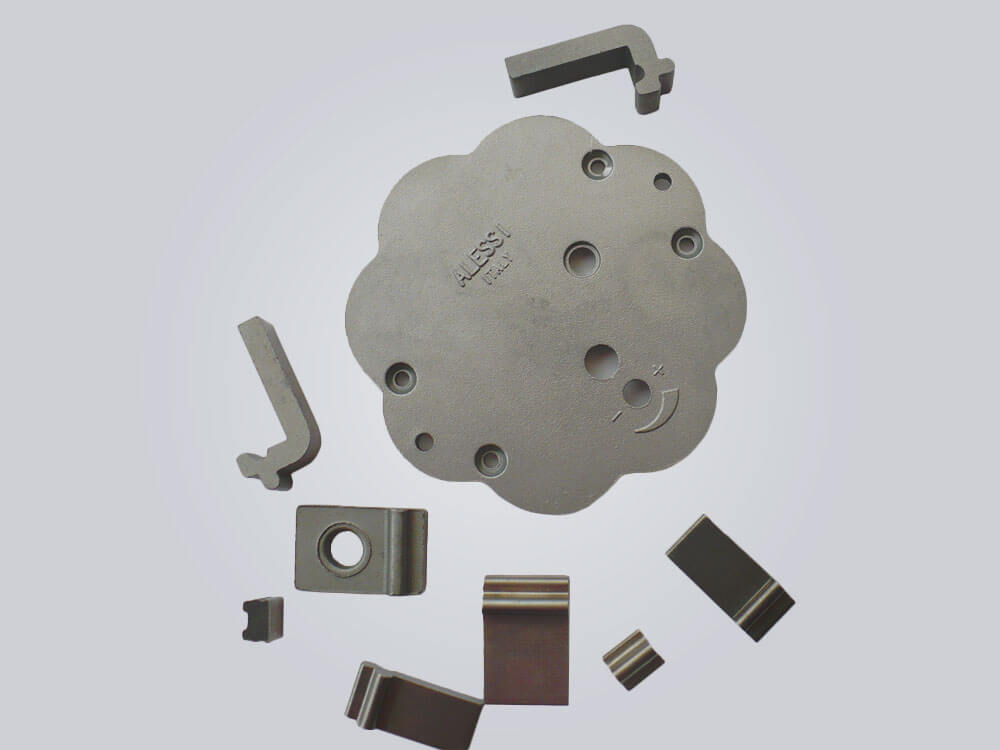

Household Electrical Appliances and Design Components

Household electrical appliances components are a typicalapplication of sintering technology; Investarm has been active in this field for over 30 years. We supply a variety of products to a number of industries, ranging from large volume applications driven by scale economics to high end luxury product applications.

Automotive Components

Automotive components are a typical application for sinteringtechnology. Investarm has been engaged in these industrial processes for over 30 years. A great wealth of experience has been gained in the production of various types of flanges.

Civil Sporting Guns

Investarm is a leader in producing firearms components for both its own production, as well as for external customers.

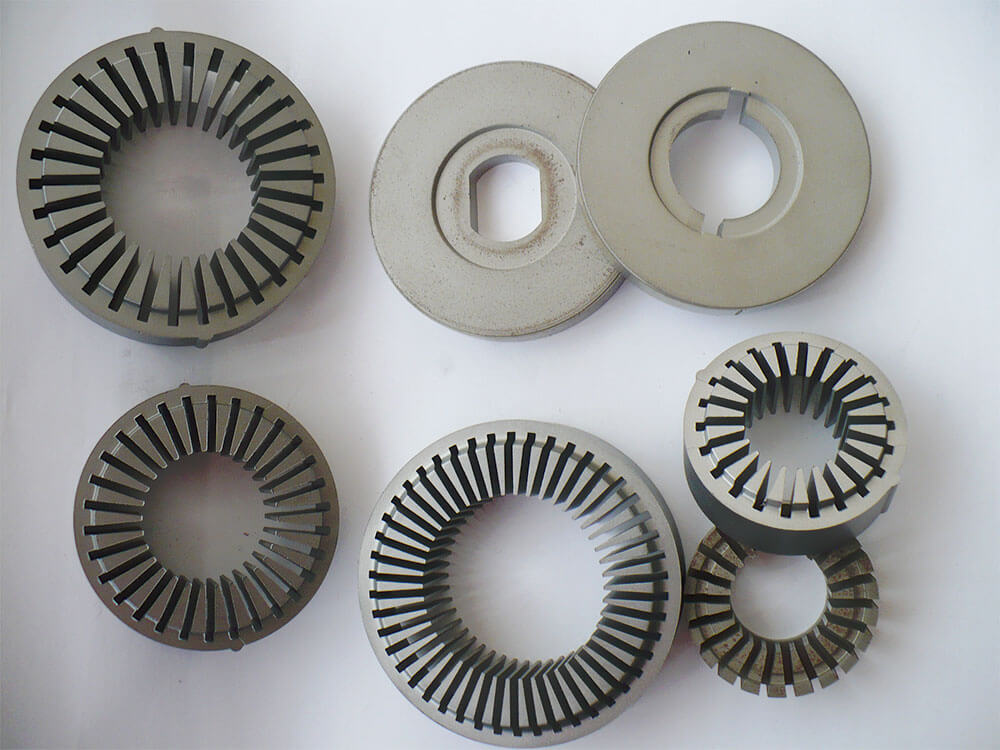

Common and Self-braking Electric Motor Components

The components of magnetic circuits have particularly complex shapes and the sintering process is the most effective way in terms of cost and production logistics in producing a viable solution at a competitive price point.

Textile Machine Components

Investarm supplies many components for textile machines, suchas: pinions, rotors, stators, magnetic circuit components, keys, buttons.

Components for Crystal Windows and Doors

These components are safety parts expected to endure high stress factors brought on by retaining and handling devices of heavy crystal sheets. For these applications, the sintered components are subjected to a copper infiltration process in order to enhance the mechanical characteristics of the product.

Garden Furniture Components

These components need to undergo a heat treatment process after sintering in order to reach the necessary strength and wear resistance characteristics.

Components for Watchmaking

These components need to be elegant, precise and suitable for galvanizing.

Components for Automatic Chairs

Gear chains for automatic chairs systems.

For a quote, please get in touch with us

We are available to help you in understanding all the advantages of sintering technology.

Latest news

There is no news.

Sintering technology performance compared to traditional production processes.

Convenience

0%

Precision

0%

Flexibility

0%

100% Made in Italy

Investarm Sinterizzati is based in Marcheno, Italy, where we have our production facilities and our commercial hub. Each step of the production process, including production of moulds, heat treatment and galvanizing treatment is performed in Italy by our local suppliers.

Get our e-book

By downloading our e-book, you can count on our advice on how to design your next sintered part.